Navigating the World of Decanter Component Manufacturing: A Comprehensive Guide

Introduction to Decanter Component Manufacturing

In the intricate world of industrial machinery, the manufacturing of decanter components emerges as a realm marked by precision, innovation, and enduring quality. Decanter centrifuges, pivotal in separating solids from liquids, rely heavily on the flawless design and manufacture of their components to function at peak efficiency. This segment of manufacturing, while niche, plays a crucial role across a broad spectrum of industries, from wastewater treatment to food and beverage production, and even in the nuanced processes of the pharmaceutical sector.

The journey of decanter component manufacturing is a tale of evolution, mirroring the advancements in technology and material science. From the early rudimentary models to today's highly sophisticated machines, the evolution of decanter components has been driven by an unyielding pursuit of efficiency, durability, and adaptability. As manufacturers delve deeper into the realms of precision engineering and digital manufacturing, the decanter components of today embody the pinnacle of industrial craftsmanship and technological integration.

As we navigate through the complexities of decanter component manufacturing, we uncover the layers of expertise, innovation, and strategic foresight that define this specialized field. This comprehensive guide aims to shed light on the processes, challenges, and advancements that shape the manufacturing of these pivotal components, offering a glimpse into the meticulous world that ensures the seamless operation of decanter centrifuges around the globe.

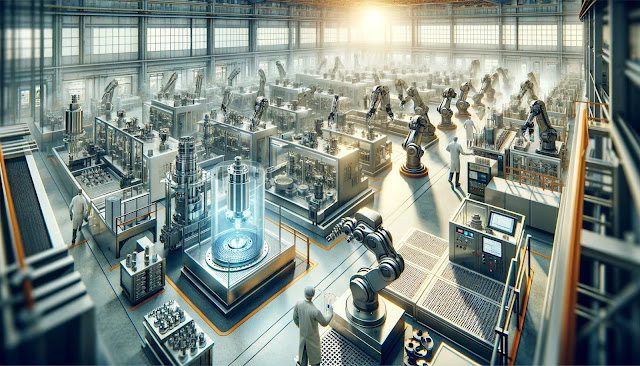

|

| Uni Abex - State-of-the-art Decanter Component Manufacturing Facility |

The Manufacturing Process of Decanter Components

Materials Selection: The Foundation of Quality

The first step in the manufacturing of decanter components is the meticulous selection of materials. Given the demanding environments in which decanters operate, materials must not only possess high strength and durability but also exhibit resistance to corrosion and wear. Commonly used materials include stainless steel varieties, due to their robustness and longevity, and advanced composites for their lightweight and corrosion-resistant properties. Each material is chosen based on the specific requirements of the application, ensuring that the final product can withstand the rigours of its operational context.

Design and Prototyping: Translating Ideas into Reality

The design phase is where ideas take shape. Utilizing advanced software tools, engineers craft detailed models of decanter components, considering factors like fluid dynamics, mechanical stress, and material compatibility. Prototyping follows, often employing 3D printing or CNC machining to create tangible models for testing and evaluation. This iterative process allows for refinements and adjustments, ensuring the component's design is optimized for performance and manufacturability.

Precision Manufacturing: Crafting with Accuracy

With the design finalized, the manufacturing phase commences. Precision machining plays a central role, with components being shaped, drilled, and finished to exact specifications. Techniques such as laser cutting and CNC machining ensure the highest levels of accuracy and consistency. Throughout this stage, rigorous quality control measures are in place, with each component undergoing detailed inspections to verify its conformity to design standards and operational requirements.

Assembly and Testing: Ensuring Reliability

The final step in the manufacturing process is the assembly of individual components into the decanter's rotating assembly. This phase demands meticulous attention to detail, as even minor misalignments can affect the decanter's performance. Following assembly, comprehensive testing is conducted to assess the decanter's efficiency, balance, and operational reliability under various conditions. Only after passing these stringent tests do the decanter components move forward to deployment in the field.

|

| Uni Abex - Aerial View of Industrial Complex |

Innovations and Advancements in Decanter Component Manufacturing

The landscape of decanter component manufacturing is continuously evolving, with innovations that push the boundaries of efficiency, sustainability, and performance. These advancements are not only a testament to the ingenuity within the field but also pave the way for new applications and improved processes across diverse industries.

Technological Breakthroughs: Elevating Precision and Efficiency

Recent years have witnessed significant technological breakthroughs in manufacturing processes. The adoption of digital twin technology, for instance, allows manufacturers to create virtual replicas of decanter components, enabling real-time monitoring and simulation of manufacturing processes. This technology aids in predicting wear and tear, optimizing design for longevity, and reducing the time from concept to production.

Another notable advancement is the integration of AI and machine learning in quality control. These technologies enable predictive maintenance, where potential issues are identified before they lead to downtime, ensuring consistent quality and reducing wastage.

Material Innovations: Pushing the Boundaries of Durability

In the realm of materials, the development of high-performance alloys and composites marks a significant leap forward. These materials offer superior strength-to-weight ratios, enhanced corrosion resistance, and greater durability under extreme conditions. For instance, the introduction of super duplex stainless steel has provided a solution for components exposed to highly corrosive environments, significantly extending the lifespan of decanter components.

Sustainable Manufacturing Practices: A Commitment to the Environment

Sustainability has become a driving force in decanter component manufacturing. Innovations in this area include the reduction of waste through lean manufacturing techniques and the recycling of materials in the production process. Manufacturers are also exploring the use of renewable energy sources in their operations, minimizing the environmental footprint of decanter component production.

Customization and Flexibility: Meeting Specific Industry Needs

The trend towards customization and flexibility in manufacturing allows for the production of decanter components tailored to specific industry requirements. Advanced manufacturing techniques, such as additive manufacturing, offer the ability to produce complex geometries and designs that were previously unattainable, opening up new possibilities for customization and innovation in component design.

Challenges and Solutions in Decanter Component Manufacturing

The manufacturing of decanter components is fraught with challenges, ranging from technical and material constraints to the ever-increasing demands for sustainability and efficiency. Understanding these challenges and the strategies employed to mitigate them offers insight into the resilience and ingenuity inherent in this industry.

Material Compatibility and Durability

One of the primary challenges in decanter component manufacturing is selecting materials that not only meet the strength and durability requirements but also are compatible with the substances they will encounter. Corrosive liquids, abrasive solids, and extreme temperatures can quickly degrade improperly chosen materials.

Solution:

Manufacturers are turning to advanced alloys and composite materials that offer enhanced resistance to corrosion and wear. Research into material science has led to the development of super duplex stainless steels and high-performance polymers, which provide the necessary durability while maintaining optimal performance.

Precision and Quality Control

The high-precision nature of decanter components means that even minute deviations in manufacturing can lead to significant performance issues. Ensuring consistent quality across batches is a formidable challenge, particularly when scaling production.

Solution:

The adoption of digital manufacturing technologies, such as CNC machining and 3D printing, allows for unparalleled precision in component production. Furthermore, integrating AI-driven quality control systems enables real-time monitoring and adjustment of manufacturing processes, ensuring each component meets stringent quality standards.

Sustainability and Environmental Impact

As global emphasis on sustainability grows, decanter component manufacturers face the challenge of reducing their environmental footprint without compromising on quality or performance.

Solution:

Many manufacturers are adopting green manufacturing practices, such as recycling materials, utilizing renewable energy, and implementing waste reduction techniques. Additionally, innovations in material science are leading to the development of more sustainable materials that do not sacrifice performance for environmental friendliness.

Customization and Adaptability

With the diverse applications of decanter centrifuges across various industries, manufacturers must be able to produce components that meet a wide range of specifications and operational conditions.

Solution:

Leveraging advanced design software and flexible manufacturing systems, manufacturers can offer customized solutions that cater to the unique needs of each industry. Additive manufacturing, in particular, provides the ability to produce complex geometries and customized designs with reduced lead times and costs.

Spotlight on Uni Abex: Leading Decanter Component Manufacturer in India

In the competitive landscape of decanter component manufacturing, Uni Abex stands out as a beacon of excellence and innovation in India. With a rich history and a commitment to quality, Uni Abex has established itself as a trusted partner for industries requiring precision-engineered decanter components.

Pioneering Manufacturing Excellence

Uni Abex's manufacturing facilities are a testament to the fusion of traditional craftsmanship and modern technology. Employing state-of-the-art machinery and adhering to stringent quality control protocols, Uni Abex ensures that each component manufactured meets the highest standards of precision and performance. Their commitment to excellence is evident in the meticulous attention to detail and the rigorous testing each product undergoes before leaving the factory floor.

Innovation at the Core

At the heart of Uni Abex's success is its relentless pursuit of innovation. By investing in research and development, Uni Abex has introduced a range of proprietary alloys and manufacturing techniques that set new benchmarks for durability and efficiency in decanter components. These innovations not only enhance the performance of the decanters but also extend their operational life, providing significant value to customers.

Tailored Solutions for Diverse Industries

Understanding the diverse needs of different sectors, Uni Abex offers customized decanter components tailored to the specific requirements of each industry. Uni Abex's engineering team collaborates closely with Indian and overseas clients to develop solutions that perfectly match their operational needs.

A Commitment to Sustainability

Uni Abex is not only focused on manufacturing excellence but also on environmental stewardship. The company has implemented several green initiatives, including waste reduction programs, energy-efficient manufacturing processes, and the use of sustainable materials, underscoring its commitment to minimizing its environmental footprint.

Uni Abex: A Symbol of Trust and Reliability

With a legacy of quality, innovation, and service, Uni Abex has earned the trust of businesses across India and beyond. Their dedication to pushing the boundaries of what's possible in decanter component manufacturing has made them a preferred choice for those in search of reliability, efficiency, and excellence.

|

| Uni Abex - Decanter Component Lab |

Conclusion

Navigating the world of decanter component manufacturing reveals a landscape marked by constant innovation, stringent quality standards, and a commitment to sustainability. From the precision-driven manufacturing processes to the cutting-edge advancements that redefine efficiency, this field is at the forefront of industrial technology.

As we have seen, Uni Abex stands out as a leader in this domain, embodying the principles of excellence, innovation, and environmental responsibility. For those seeking the pinnacle of decanter component manufacturing in India, Uni Abex offers not just products, but solutions that drive success.

To discover more about Uni Abex's offerings and how they can enhance your operations, we invite you to visit www.uniabex.com. Explore the future of decanter component manufacturing with a partner that's committed to pushing the boundaries of excellence.

Comments

Post a Comment